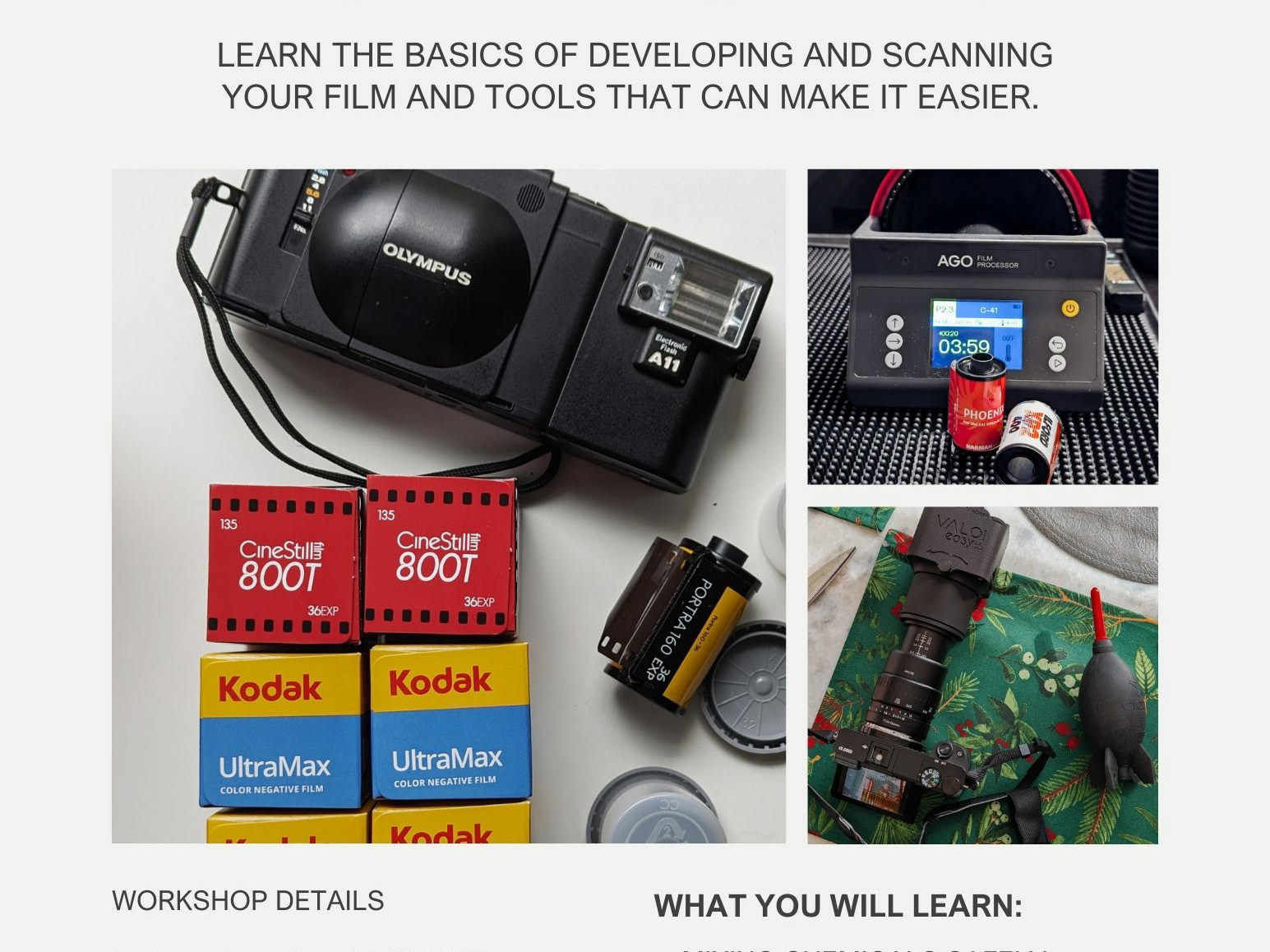

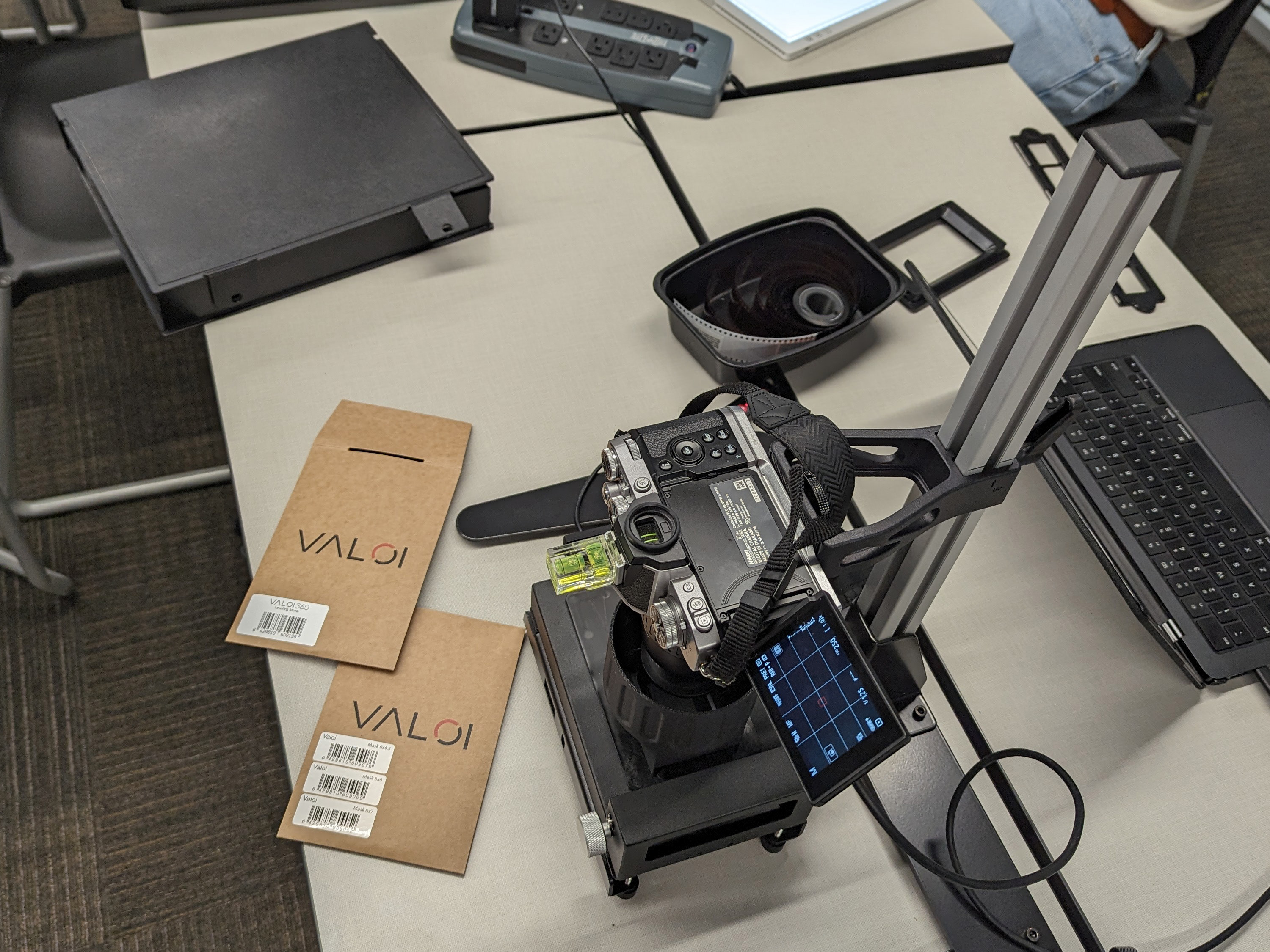

Overview of what developing is and how it works -

Developing film involves a chemical process that turns light into a visible, permanent photograph.

What is film made of?: Film is made up of a few parts - the film base (which is the clear shiny plastic clear strip) and the emulsion (the dull side). This dull side of the film is where the magic happens.

It's a thin gelatin coating that has been blended with silver halide (salt) crystals. You’ll often see older darkroom prints as “silver gelatin prints” - that’s where that term originates. For black and white film - its purely silver salt that is activated by visible light - usually across the whole spectrum. In color film - the silver crystals are bonded to colored dyes that are activated by either the yellow, blue, or magenta part of visible light that hits them.

These activated crystals - once they’ve been hit by light - are called the latent image.

Film Developing Terms:

Latent Image Formation: When a film is exposed to light in a camera, light-sensitive silver halide crystals in the emulsion layer react. The light creates tiny, invisible clumps of metallic silver at the sites of exposure, forming a latent image.

Developing: The film is placed in a developer solution, which reduces the exposed silver halide crystals to black metallic silver. This makes the latent image visible (albeit as a negative, or the inverse) Unexposed crystals remain unaffected at this stage.

Stopping: A stop bath (typically a weak acidic solution (vinegar essentially)) halts the development process by neutralizing the developer.

Fixing: The film is immersed in a fixer solution, which dissolves the unexposed silver halide crystals, making the image permanent and light-insensitive.

Washing: The film is thoroughly washed with water to remove all chemical residues, preventing degradation over time.

Drying: The film is dried in a dust-free environment.

Mixing The Chemicals and Chemical Best Practices

Procure Safety and Mixing Equipment

Use a mixing jug slightly larger than your desired final volume to avoid spills.

Have accurate measuring tools (e.g., containers, beakers, pipettes, or syringes) for precise measurements in milliliters or ounces.)

Use clean stir sticks to avoid contamination.

Keep the Material Safety Data Sheet (MSDS) and mixing instructions (usually provided with the chemicals) accessible.

Wear protective gear as needed:

- Gloves (optional but recommended).

- Eye protection (optional for added safety).

- Apron (optional for protecting clothing).

Review Documentation: Before mixing, read the MSDS to understand the risks of the chemicals and review the mixing instructions. Determine the correct strength for your intended use.

Understand Terminology:

- Powder vs. Concentrate: Some chemicals come as dry powders, while others are liquid concentrates.

- Stock vs. Working Solution: A stock solution is a concentrated form that you dilute to create a working solution.

- Mixing Ratios: Learn how to interpret ratios like 1:1 (e.g., for 1 liter of working solution, mix 500 mL of chemical concentrate/stock solution with 500 mL of water)

Storage of Chemicals

Use bottles or jugs specifically rated for chemical storage.

Minimize air exposure: Opt for collapsible containers or use containers close to your final chemical volume to reduce oxygen, which can degrade chemicals.

Protect from light: Store chemicals in light-proof containers or keep them in a cool, dark place to avoid light damage.

Safe Disposal of Photo Chemicals

Developer and Stop Bath: These can often be diluted and safely disposed of down the drain with plenty of water, depending on local regulations. Check with your municipal waste authority for guidance. (At UDC, we capture all developer and fixer and properly dispose of it. Stop bath is essentially vinegar and is safe to put down the drain with water.)

Fixer: Do not pour fixer down the drain. Fixer contains dissolved silver, which is a heavy metal and an environmental hazard. Silver can contaminate water supplies and harm aquatic life.

Collect used fixer in a dedicated container. Many photo labs or waste disposal services can process it to recover the silver.

If recycling isn't an option, dispose of it through a certified hazardous waste collection service.

Proper disposal of photo chemicals is essential to prevent environmental damage and comply with local regulations. Always check local guidelines to ensure you're following the law.

Retrieving Film Leaders or Cracking Film Canisters

Method 1: Using a Film Leader Retriever

This method requires a bit more finesse but is commonly used in professional film labs.

Here’s how it works:

A film leader retriever is used to grab the end of the film and pull it out of the canister.

The film leader is trimmed and fed into the machine (or, in our case, prepared for loading onto the reel).

In the lab, this method is clean and efficient. After the film is processed, the empty canister is often recycled.

Types of Leader Retrievers

There are two main types of film leader retrievers:

The standard design.

The Ars Imago style (my personal favorite).

Experiment to see which one works best for you.

Method 2: Cracking Open the Canister

Also known as the "can opener method," this is straightforward:

Place the canister in the dark bag.

Use a can opener to pry it open and remove the film entirely.

---

Pros and Cons of Each Method

Film Leader Retriever Method

Pros:

Cleaner process; limits film handling, reducing the risk of scratches.

Helps save the canister for bulk rolling or reuse.

Ideal for beginners as it minimizes the time the film is exposed outside the canister or tank.

If you struggle to load the reel, you can wind the film back into the canister, take a break, and try again.

Cons:

Requires more precision and practice.

Can be trickier with certain reels (e.g., metal reels) because not all the film is accessible at once.

Can Opener Method

Pros:

Simple and quick; no special tools or skills required.

Makes all the film accessible, which can speed up loading onto reels (especially metal ones).

Cons:

If you can’t load the reel properly, you’ll need to seal the tank before removing your hands from the dark bag, or risk light exposure. Any light entering the bag, even briefly, can irreversibly damage the film.

Can’t reuse rolls for bulk rolling.

Ultimately, both methods have their place. The leader retriever method offers more control and cleanliness, while the can opener method is simpler and better suited for metal reels. Experiment to see which one fits your workflow!

Working in Dark Bags

Why a dark bag?

Film is extremely sensitive to light. Even light our eyes don't detect can cause irreversible damage to a piece of film. Most people do not have access to a completely dark space, so a dark bag allows anyone to process film wherever they are.

Plan for Use

Working in a dark bag requires planning ahead. Make sure your dark bag has everything in it that you will need prior to adding your film. This includes all parts of the film tank, reels, scissors, and can opener for opening the film reel (even if you have done the leader retrieval method this can be a good backup)

Working in a dark bag requires planning ahead. Make sure your dark bag has everything in it that you will need prior to adding your film. This includes all parts of the film tank, reels, scissors, and can opener for opening the film reel (even if you have done the leader retrieval method this can be a good backup)

Zip it Tight (And Keep it Safe)

Be sure to zip your dark bag completely, and fold over any additional flaps that are designed to keep light out of the bag.

Also be sure to keep your bag safe - repeated folding of a bag along the same seam, sharp points from scissors or other objects, etc. can cause holes to appear in your bag. A holey dark bag is no use to you and can ruin your film. Inspect your bag for damage if you’re in doubt.

Determining Development Time, Filling Development Tanks, and Agitation Methods

So now we’ve gotten through the hard part. Once your film reels are loaded and the tanks are capped, you can move on to development.

Consult Massive Dev Chart/Instructions

It is important to note that for black and white film processing, each film stock will be different. You will need to know the recommended development time for each film you use and try to keep the same types (or similar development times) together for the best results.

Consulting your film’s data sheet or Massive Dev Chart can give you a good place to start. Then you can experiment from there, making creative choices about what kind of developer, how long, how to agitate, and more to control the end product. We’ll be keeping it simple and just following the Massive Dev Chart base recommendations.

Once you’ve located your film stock and developer on the Massive Dev chart, make a note or plan to use the built in time for the Massive Dev Chart app.

Choosing Agitation method

Your chosen method of development will have a standard form of agitation. For us, we’ll be using the “inversion” method. This means we will slowly invert the tank while rotating so that we create a consistent but randomized swirl of chemical through the tank.

Things to avoid -

Too much agitation too quickly can create bubbles. Bubbles in the chemical can show up on your film, leaving uneven patches of development. Tap your tank lightly after inverting to loosen any small bubbles that may have formed on the surface of your film, but not too much, because too much tapping can also cause the developer to foam.

Inverting too quickly without rotating can also create areas on your film that are over or underdeveloped relative to the rest of the roll. These will appear as bands or streaks on your developed film.

Not filling your development tank to the recommended level can leave the portion of your film that is above the “water line” undeveloped.